"mkbruin, Atlas VP" (mkbruin)

"mkbruin, Atlas VP" (mkbruin)

03/16/2018 at 09:05 • Filed to: None

0

0

5

5

"mkbruin, Atlas VP" (mkbruin)

"mkbruin, Atlas VP" (mkbruin)

03/16/2018 at 09:05 • Filed to: None |  0 0

|  5 5 |

What’s the coolest automotive tech that never made it to production? I’m talking about tangible prototyped tech that dropped off the map.

I’m choosing Ford’s experiments with organic polymers... Specifically the pe-war “Soybean Car”.

What exactly was in that compound is unprovable. According to Ford’s project manager for the Soybean Car, it was “… soybean fiber in a phenolic resin with formaldehyde used in the impregnation.” Needless to say, Ford loved to demo his ‘plastic car’ by hitting it with an axe or a sledgehammer and showing no damage. Ford passed just a few years later, the formula vanished, the car itself was destroyed, and the tech never saw the light of day.

WilliamsSW

> mkbruin, Atlas VP

WilliamsSW

> mkbruin, Atlas VP

03/16/2018 at 09:25 |

|

And never will make it into production, either...

arl

> mkbruin, Atlas VP

arl

> mkbruin, Atlas VP

03/16/2018 at 09:25 |

|

People in the window “Did you give him the foam sledgehammer? Otherwise, this isn’t going to end well.”

BlueMazda2 - Blesses the rains down in Africa, Purveyor of BMW Individual Arctic Metallic, Merci Twingo

> mkbruin, Atlas VP

BlueMazda2 - Blesses the rains down in Africa, Purveyor of BMW Individual Arctic Metallic, Merci Twingo

> mkbruin, Atlas VP

03/16/2018 at 09:28 |

|

Turn signals in BMWs.

I’m aware all other cars have them, but it would’ve been nice to see them make it into production on BMWs.

Ash78, voting early and often

> mkbruin, Atlas VP

Ash78, voting early and often

> mkbruin, Atlas VP

03/16/2018 at 09:30 |

|

Brake lights with variable brightness based on pedal pressure or g forces.

IIRC BMW prototyped this about 10 years ago but it ran afoul of some obscure Euro and NHTSA rules about lighting (which are mostly stupid).

ranwhenparked

> mkbruin, Atlas VP

ranwhenparked

> mkbruin, Atlas VP

03/16/2018 at 19:29 |

|

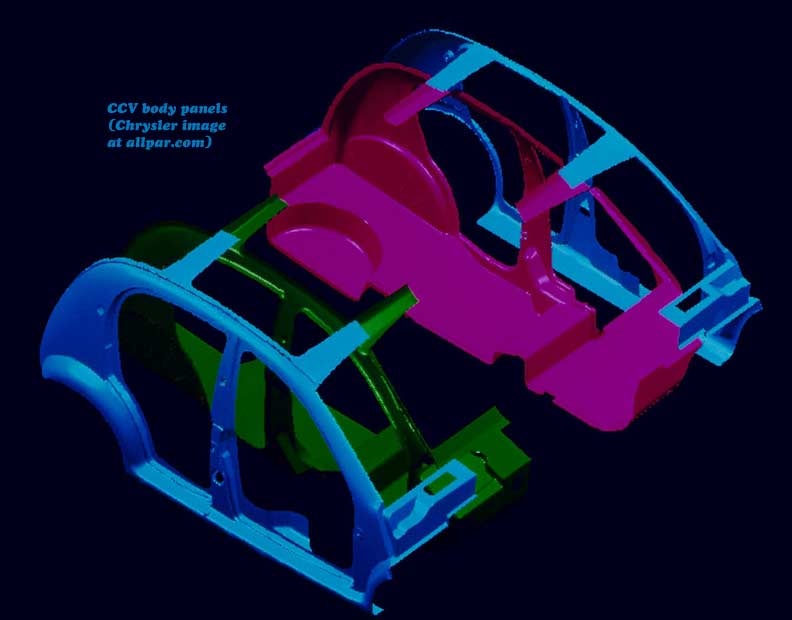

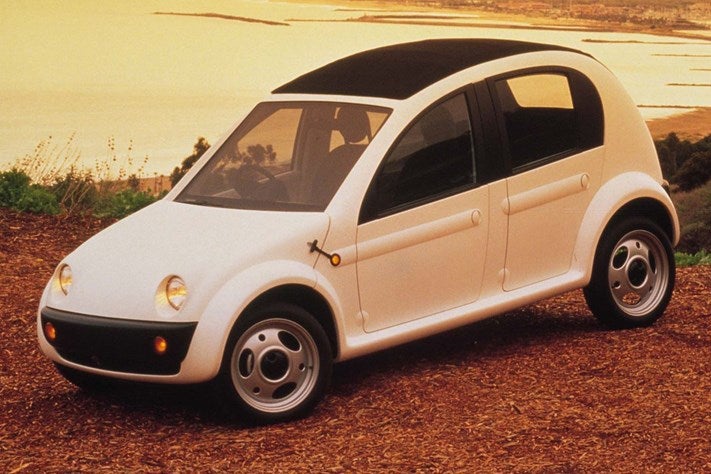

The plastic bodies Chrysler was working on at the time Daimler-Benz took them over.

Molded in a couple of large sections, then glued together. The CCV concept supposedly weighed 400 lbs less than an equivalent steel body, and, because the plastic was thinner than steel, it had 18% more useable interior room. Tooling costs would have been 2/3 lower, materials costs 1/3 lower, and they were shooting for assembly time of 6 1/2 hours for a complete car.

Allegedly, they performed “satisfactorily” in side impact crash tests, but poorly in front/rear tests, though they did quite well in roof crush tests. Problems that were solvable, but the issue of making body repairs after a crash was a harder one. Bob Lutz was pretty serious about the thing though, and Chrysler was fully committed to it. But, Daimler cancelled the whole thing when they bought the company.

Realistically, this was a lot of money to spend on technology intended for a cheap people’s car for the developing world. Some of the R&D might have eventually been applied to American and European market cars, but, had a version of the CCV gone into production, I doubt it would have done much better than the Nano.